Material treatment

PVD (Physical Vapor Deposition) by Dekracoat BV

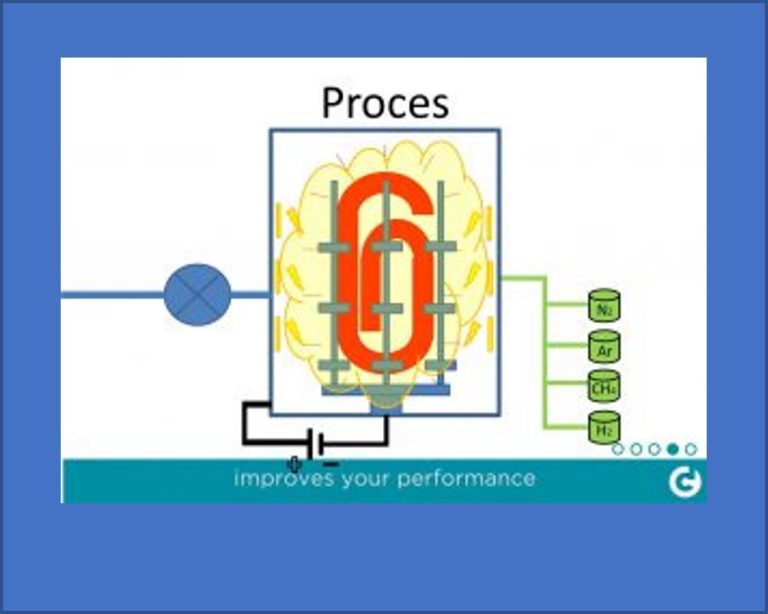

PVD is the physical application of a wear-resistant layer in a vacuum environment. The PVD process (Physical Vapor Deposition) takes place under high vacuum, at a high temperature. The materials like Wolfram, Chromium, Titanium and Aluminium are evaporated on the tooling (for example punches, molds, drills & mills). During the process, some gasses

Presentation and poster will be available at 17 april 2025